What are the key considerations and applications of aluminum alloy welding wire in the welding industry?

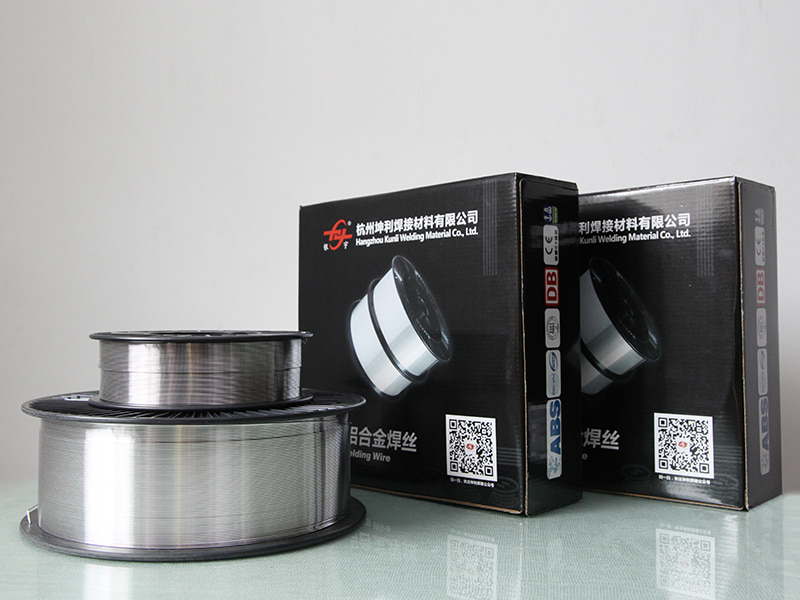

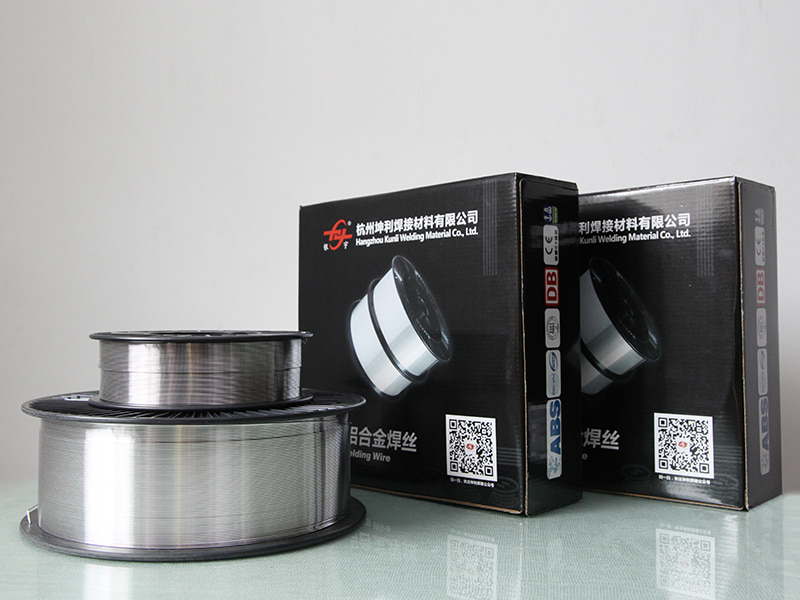

1. Alloy Composition: Aluminum alloy welding wire comes in various compositions, each suited for specific applications and base metals. It is crucial to select the appropriate alloy composition that matches the base metal being welded. Different aluminum alloys have distinct mechanical properties and characteristics, such as strength, corrosion resistance, and heat conductivity. Choosing the correct alloy composition ensures proper metallurgical compatibility and optimal weld quality.

2. Wire Diameter and Form: Aluminum alloy welding wire is available in different diameters and forms, such as solid wire or flux-cored wire. The selection of the wire diameter depends on factors like the thickness of the base metal and the welding process being employed. Thinner wires are generally used for thinner materials, while thicker wires are suitable for heavier applications. Additionally, the choice between solid wire and flux-cored wire depends on the welding process, equipment, and specific application requirements.

3. Wire Cleanliness: Aluminum is susceptible to oxide formation, which can affect weld quality. Therefore, cleanliness of the aluminum alloy welding wire is crucial. Oxide removal and prevention measures, such as proper storage, handling, and cleaning techniques, should be implemented to maintain the cleanliness of the welding wire. Clean welding wire ensures improved arc stability, reduced porosity, and enhanced weld appearance.

Applications of Aluminum Alloy Welding Wire:

1. Automotive Industry: Aluminum alloy welding wire finds extensive use in the automotive industry for joining aluminum components. As the industry increasingly adopts lightweight construction techniques, aluminum is being used in the manufacturing of vehicle bodies, frames, panels, and structural components. Aluminum alloy welding wire enables the fabrication and repair of these aluminum-based automotive parts, providing high-strength and durable welds.

2. Aerospace Industry: Aluminum alloys are widely used in the aerospace industry due to their lightweight properties and corrosion resistance. Aluminum alloy welding wire plays a critical role in the fabrication and repair of aircraft components, including fuselage sections, wings, engine components, and fuel tanks. The use of high-quality aluminum alloy welding wire ensures the integrity and reliability of these critical aerospace structures.

3. Construction Industry: Aluminum alloys are employed in the construction industry for various applications, such as architectural structures, window frames, door frames, and roofing systems. Aluminum alloy welding wire enables the joining of aluminum components, providing structural integrity and durability. The lightweight nature of aluminum alloys contributes to ease of construction, while the weld strength ensures long-term performance.

4. Marine Industry: Aluminum alloys are widely utilized in the marine industry due to their excellent corrosion resistance in saltwater environments. Aluminum alloy welding wire is instrumental in fabricating and repairing marine vessels, including boats, ships, and offshore structures. The welds created using aluminum alloy welding wire withstand the harsh marine conditions and maintain structural integrity.

5. Manufacturing and Fabrication: Aluminum alloy welding wire is essential in various manufacturing and fabrication industries, where aluminum and aluminum alloy components are used. This includes industries such as consumer electronics, furniture, industrial equipment, and machinery. Aluminum alloy welding wire enables the fabrication and assembly of aluminum-based products, ensuring strong and reliable welds.

2. Wire Diameter and Form: Aluminum alloy welding wire is available in different diameters and forms, such as solid wire or flux-cored wire. The selection of the wire diameter depends on factors like the thickness of the base metal and the welding process being employed. Thinner wires are generally used for thinner materials, while thicker wires are suitable for heavier applications. Additionally, the choice between solid wire and flux-cored wire depends on the welding process, equipment, and specific application requirements.

3. Wire Cleanliness: Aluminum is susceptible to oxide formation, which can affect weld quality. Therefore, cleanliness of the aluminum alloy welding wire is crucial. Oxide removal and prevention measures, such as proper storage, handling, and cleaning techniques, should be implemented to maintain the cleanliness of the welding wire. Clean welding wire ensures improved arc stability, reduced porosity, and enhanced weld appearance.

Applications of Aluminum Alloy Welding Wire:

1. Automotive Industry: Aluminum alloy welding wire finds extensive use in the automotive industry for joining aluminum components. As the industry increasingly adopts lightweight construction techniques, aluminum is being used in the manufacturing of vehicle bodies, frames, panels, and structural components. Aluminum alloy welding wire enables the fabrication and repair of these aluminum-based automotive parts, providing high-strength and durable welds.

2. Aerospace Industry: Aluminum alloys are widely used in the aerospace industry due to their lightweight properties and corrosion resistance. Aluminum alloy welding wire plays a critical role in the fabrication and repair of aircraft components, including fuselage sections, wings, engine components, and fuel tanks. The use of high-quality aluminum alloy welding wire ensures the integrity and reliability of these critical aerospace structures.

3. Construction Industry: Aluminum alloys are employed in the construction industry for various applications, such as architectural structures, window frames, door frames, and roofing systems. Aluminum alloy welding wire enables the joining of aluminum components, providing structural integrity and durability. The lightweight nature of aluminum alloys contributes to ease of construction, while the weld strength ensures long-term performance.

4. Marine Industry: Aluminum alloys are widely utilized in the marine industry due to their excellent corrosion resistance in saltwater environments. Aluminum alloy welding wire is instrumental in fabricating and repairing marine vessels, including boats, ships, and offshore structures. The welds created using aluminum alloy welding wire withstand the harsh marine conditions and maintain structural integrity.

5. Manufacturing and Fabrication: Aluminum alloy welding wire is essential in various manufacturing and fabrication industries, where aluminum and aluminum alloy components are used. This includes industries such as consumer electronics, furniture, industrial equipment, and machinery. Aluminum alloy welding wire enables the fabrication and assembly of aluminum-based products, ensuring strong and reliable welds.

PREV:What are the key considerations for selecting the right aluminum alloy welding wire for specific applications, and how does it impact the quality and efficiency of the welding process?

NEXT:What are the key applications and advantages of using aluminum TIG wire in the welding industry, and how does it contribute to high-quality welds and efficient welding processes?

NEXT:What are the key applications and advantages of using aluminum TIG wire in the welding industry, and how does it contribute to high-quality welds and efficient welding processes?

Related Products

-

View More

View More

5154 Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

Aluminum Welding Wire ER5183

-

View More

View More

Aluminum Welding Wire ER5356

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

English

English Deutsch

Deutsch

English

English Deutsch

Deutsch