What are the advantages of aluminum welding wire?

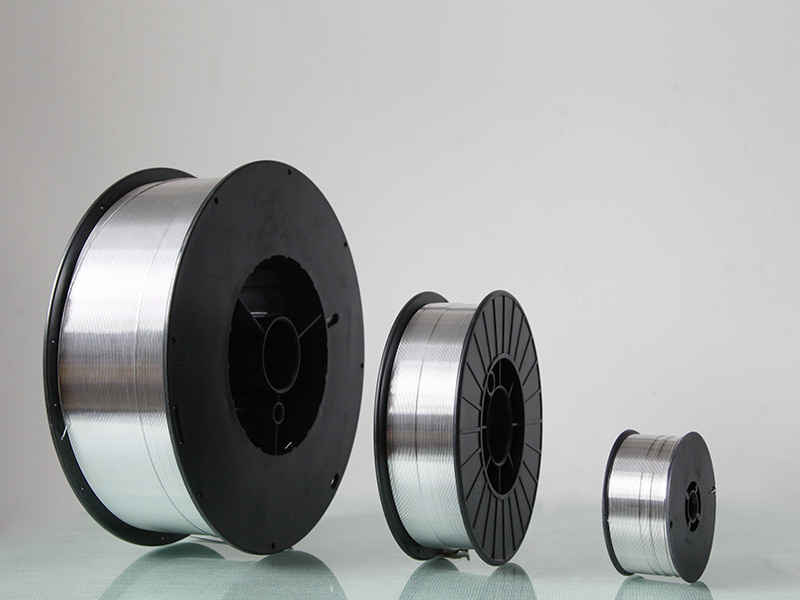

Aluminum welding wire is a type of wire used for welding aluminum materials. It is used in conjunction with a welding power supply and a welding torch, and is fed through the torch and melted by the heat of the flame to create a strong joint between two aluminum pieces. Aluminum welding wire is available in various diameters and alloys to suit different welding applications. It is generally considered to be more difficult to work with than steel welding wire because aluminum is more prone to overheating and has a lower melting point. However, aluminum welding wire has the advantage of being lightweight and corrosion-resistant, making it useful for many types of projects.

1. Lightweight: Aluminum is much lighter than steel, so aluminum welding wire is much lighter than steel welding wire. This makes it easier to work with and reduces the strain on the welder's arms and shoulders.

2. Corrosion-resistant: Aluminum is resistant to corrosion, so aluminum welding wire is also resistant to corrosion. This makes it suitable for use in outdoor or damp environments where steel welding wire would be prone to rusting.

3. Good conductivity: Aluminum is a good conductor of electricity, so aluminum welding wire is also a good conductor. This makes it ideal for use in electrical and electronic applications where a strong, conductive joint is required.

4. Non-magnetic: Aluminum is non-magnetic, so aluminum welding wire is also non-magnetic. This can be useful in applications where the presence of a magnetic field is undesirable.

5. Easy to work with: Aluminum welding wire is generally considered to be easier to work with than steel welding wire because it has a lower melting point and is less prone to overheating. This makes it a good choice for beginner welders or those who are new to welding aluminum.

Related Products

-

View More

View More

5154 Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

Aluminum Welding Wire ER5183

-

View More

View More

Aluminum Welding Wire ER5356

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

English

English Deutsch

Deutsch

English

English Deutsch

Deutsch