How to ensure the corrosion resistance of the weld when using Aluminum Alloy Wire for welding?

In the field of marine engineering, aluminum alloy structures often face the challenge of seawater corrosion. When using Aluminum Alloy Wire for welding aluminum alloy parts, how to ensure the corrosion resistance of the weld to extend the service life of the structure?

In the field of marine engineering, aluminum alloy structures face particularly severe challenges of seawater corrosion. In order to ensure the corrosion resistance of the weld when using Aluminum Alloy Wire for welding aluminum alloy parts, thereby extending the service life of the structure, the following measures can be taken:

Choose suitable aluminum alloy welding materials:

According to the specific needs of marine engineering, select aluminum alloy welding materials with excellent corrosion resistance. For example, some aluminum alloy series (such as 5 series and 6 series) are widely used in the field of marine engineering due to their good corrosion resistance.

Optimize welding process parameters:

Precisely control process parameters such as welding current, voltage, welding speed and welding sequence to ensure the quality of the weld. Appropriate welding parameters can reduce the heat input during welding, thereby reducing the risk of corrosion caused by overheating in the weld area.

Use anti-corrosion coating or surface treatment: After welding is completed, the weld and surrounding areas are treated with anti-corrosion coating, such as thermal spraying of zinc, aluminum or its alloy coating, to improve the corrosion resistance of the weld.

Surface treatment methods such as anodizing and electrophoretic coating can also be used to enhance the corrosion resistance of the aluminum alloy surface.

Use electrochemical protection technology: For welds in key areas, electrochemical protection technology, such as cathodic protection, can be considered. By applying current to the aluminum alloy structure, a cathodic protection layer is formed, thereby reducing the occurrence of corrosion.

Control impurities and contamination during welding: The introduction of impurities and contaminants, such as oil, moisture, oxides, etc., should be strictly controlled during welding. These impurities will reduce the corrosion resistance of the weld.

Welding quality inspection and monitoring: After welding, the weld is quality inspected and monitored to ensure that the weld is free of defects and cracks. These defects may become the starting point of corrosion and reduce the corrosion resistance of the structure.

Regular maintenance and inspection: Regularly maintain and inspect the aluminum alloy structure to detect and deal with corrosion problems in a timely manner. For areas with severe corrosion, they should be repaired or replaced in a timely manner.

By taking the above measures, the corrosion resistance of the weld when using Aluminum Alloy Wire for welding aluminum alloy parts can be ensured, thereby extending the service life of the structure. It should be noted that different marine engineering environments have different requirements for the corrosion resistance of aluminum alloy structures, so in practical applications, appropriate anti-corrosion measures should be selected according to specific circumstances.

NEXT:When welding with Aluminum Welding Wire, how to control welding parameters to avoid excessive heat generation?

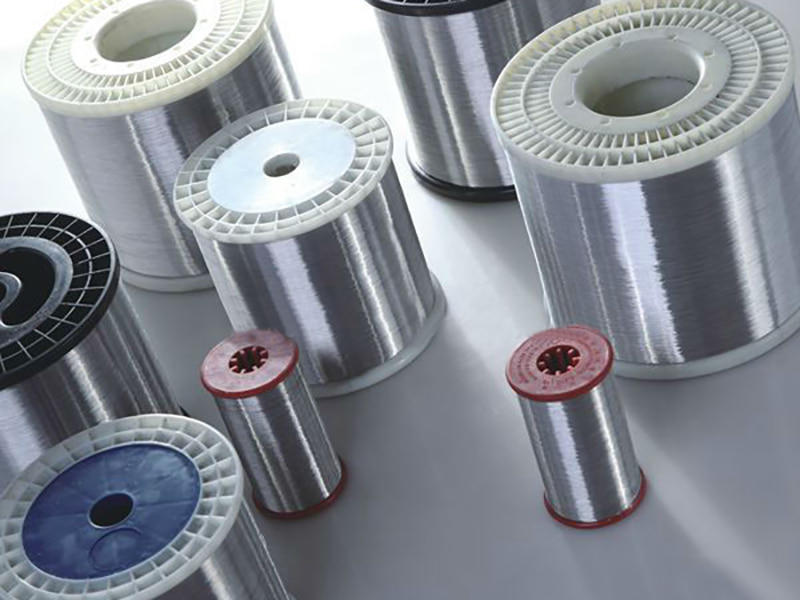

Related Products

-

View More

View More

5154 Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

ER5183 Aluminum Welding Wire

-

View More

View More

ER5356 Aluminum Welding Wire

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

English

English Deutsch

Deutsch

English

English Deutsch

Deutsch