Aluminum Alloy Wire Emerges as a Game Changer in the Electrical Industry

Aluminum alloy wire has become the latest buzz in the electrical industry due to its many benefits, including improved performance and reduced cost. This lightweight and durable material is set to transform the way electricity is transmitted and distributed in the coming years.

Aluminum alloy wire is a type of wire that is made from a combination of aluminum and other metals such as copper, magnesium, and silicon. The result is a strong, lightweight material that is ideal for use in a wide range of applications, including electrical wiring.

One of the main benefits of aluminum alloy wire is its superior conductivity. This means that electricity can flow through it with less resistance, resulting in less energy loss and improved efficiency. Additionally, aluminum alloy wire is more lightweight than traditional copper wire, making it easier to handle and transport.

Another advantage of aluminum alloy wire is its durability. Unlike copper wire, which is prone to corrosion and damage over time, aluminum alloy wire is highly resistant to these factors. This means that it can be used in harsh environments without deteriorating or losing its conductivity.

Aluminum alloy wire has a wide range of applications in the electrical industry. It can be used for power transmission and distribution, as well as in motors and generators. It is also commonly used in the construction of electrical wiring and cabling.

In addition to these applications, aluminum alloy wire is also being used in emerging technologies such as electric vehicles and renewable energy systems. Its lightweight and durable properties make it an ideal material for these applications, where weight and efficiency are key factors.

While aluminum alloy wire offers many benefits, there are also some challenges associated with its use. One of the main challenges is that it is more difficult to work with than copper wire, due to its lower tensile strength. This means that it requires more careful handling during installation and may require specialized tools and techniques.

Another challenge is that aluminum alloy wire has a higher thermal expansion coefficient than copper wire. This means that it expands more when it is heated, which can cause it to loosen or break over time. To overcome this challenge, manufacturers must carefully design and test their products to ensure that they are suitable for use in a wide range of environments.

Aluminum alloy wire is a type of wire that is made from a combination of aluminum and other metals such as copper, magnesium, and silicon. The result is a strong, lightweight material that is ideal for use in a wide range of applications, including electrical wiring.

One of the main benefits of aluminum alloy wire is its superior conductivity. This means that electricity can flow through it with less resistance, resulting in less energy loss and improved efficiency. Additionally, aluminum alloy wire is more lightweight than traditional copper wire, making it easier to handle and transport.

Another advantage of aluminum alloy wire is its durability. Unlike copper wire, which is prone to corrosion and damage over time, aluminum alloy wire is highly resistant to these factors. This means that it can be used in harsh environments without deteriorating or losing its conductivity.

Aluminum alloy wire has a wide range of applications in the electrical industry. It can be used for power transmission and distribution, as well as in motors and generators. It is also commonly used in the construction of electrical wiring and cabling.

In addition to these applications, aluminum alloy wire is also being used in emerging technologies such as electric vehicles and renewable energy systems. Its lightweight and durable properties make it an ideal material for these applications, where weight and efficiency are key factors.

While aluminum alloy wire offers many benefits, there are also some challenges associated with its use. One of the main challenges is that it is more difficult to work with than copper wire, due to its lower tensile strength. This means that it requires more careful handling during installation and may require specialized tools and techniques.

Another challenge is that aluminum alloy wire has a higher thermal expansion coefficient than copper wire. This means that it expands more when it is heated, which can cause it to loosen or break over time. To overcome this challenge, manufacturers must carefully design and test their products to ensure that they are suitable for use in a wide range of environments.

PREV:5 Essential Tips for Choosing and Using Aluminum Welding Wire

NEXT:New Aluminum Welding Wire Developed for Improved Welding Results

NEXT:New Aluminum Welding Wire Developed for Improved Welding Results

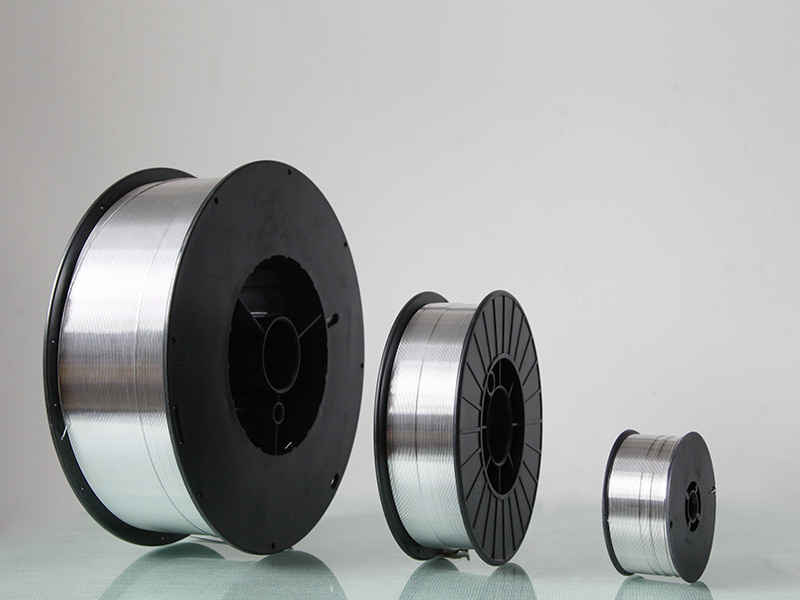

Related Products

-

View More

View More

5154 Aluminum Alloy Welding Wire

-

View More

View More

ER4043 Silicon Aluminum Welding Wire

-

View More

View More

ER4047 Aluminum Mig Welding Wire

-

View More

View More

ER5154 Al-Mg Alloy Wire

-

View More

View More

ER5087 Magnesium Aluminum Welding Wire

-

View More

View More

Aluminum Welding Wire ER5183

-

View More

View More

ER5356 Aluminum Welding Wire

-

View More

View More

ER5554 Aluminum Welding Wire

-

View More

View More

ER5556 Aluminum Welding Wire

-

View More

View More

ER1100 Aluminum Welding Wire

-

View More

View More

ER5754 Aluminum Welding Wire

-

View More

View More

ER2319 Aluminum Welding Wire

English

English Deutsch

Deutsch

English

English Deutsch

Deutsch